PPR Pipes

PPRC Pipes

PPRC pipes made of polypropylene by Parthiv Polymers are appropriate for use with both hot and cold potable water. They can withstand working temperatures of up to 100°C and have a lifespan of more than 50 years at a working pressure of 10 bar.

Our PPRC pipes range in size from 20mm (1/2″) to 315mm (12″) and are constructed using 100% new raw materials from South Korea and Borealis, which prevents bacterial growth and makes the product very hygienic and non-toxic.

Specifications

- Material : Polypropylene Random Copolymer (PPRC)

- Size : 20mm(1/2’’) to 315mm(12’’)

- Pressure : PN10/PN16/PN20

- Color : Green, white, grey, other customized color

- Length : 3 meters & 5 meters per piece

- Standard : IS 15801, DIN 8077

- Connection : Socket fusion

Application Areas

waterline

Heating system

Environmental

Solar plant

PP/PPRC/HDPE Pipes and PPRC WALL THICKNESS CHART WITH DIMENSIONS OF ID (In mm)

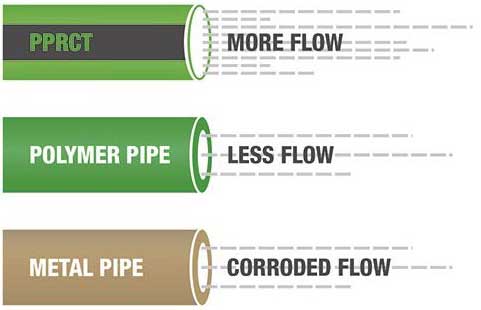

PPRC claims exceptional technical figures. No other polymer pipe gives such mechanical strength and flow with better temperature resistance , that also assure very less heat loss with great impact strength and less thermal expansion.

PPRC piping are developed with special grade of polypropylene and glass reinforcement which fulfills the Industrial needs The technical comparison clearly shows how our PPRC pipes are superior over other piping system.

Energy saving

Technical Evalution Of PPRC Pipe with Aluminium and Metal Pipes

Application Areas

waterline

Environmental

Process Line

Chemical Line

| Size (mm) | Size (inch) | PN10 | PN12.5 | PN16 | PN20 | ||||

| Thickness (mm) | Weight (kg/meter) | Thickness (mm) | Weight (kg/meter) | Thickness (mm) | Weight (kg/meter) | Thickness (mm) | Weight (kg/meter) | ||

| 20 | 1/2’’ | 2 | 0.114 | 2.3 | 0.127 | 2.8 | 0.148 | 3.4 | 0.172 |

| 25 | 3/4’’ | 2.3 | 0.163 | 2.8 | 0.191 | 3.5 | 0.231 | 4.2 | 0.267 |

| 32 | 1’’ | 2.9 | 0.259 | 3.6 | 0.313 | 4.4 | 0.371 | 5.4 | 0.436 |

| 40 | 1 1/4’’ | 3.7 | 0.411 | 4.5 | 0.488 | 5.5 | 0.578 | 6.7 | 0.676 |

| 50 | 1 1/2’’ | 4.6 | 0.631 | 5.6 | 0.75 | 6.9 | 0.894 | 8.3 | 1.041 |

| 63 | 2’’ | 5.8 | 0.993 | 7.1 | 1.209 | 8.6 | 1.404 | 10.5 | 1.655 |

| 75 | 2 3/4’’ | 6.8 | 1.377 | 8.4 | 1.679 | 10.3 | 2 | 12.5 | 2.345 |

| 90 | 3’’ | 8.2 | 1.957 | 10.1 | 2.422 | 12.3 | 2.869 | 15 | 3.487 |

| 110 | 4’’ | 10 | 3.013 | 12.3 | 3.61 | 15.1 | 4.301 | 18.3 | 5.037 |

| 160 | 6’’ | 14.6 | 6.385 | 17.9 | 7.63 | 21.9 | 8.927 | 26.6 | 10.601 |

Test & Inspection :

| TEST | REQUIREMENT | RESULT |

| Visual Inspection | There is no color aberration for PPR pipe,PPR pipe surface must be smooth, without hollow,bubble,visible impurity or any other defect | Qualified |

| Non-Transparency Test | PPR pipe shouldn’t be transparent | Light Proof |

| Vertical Reversion Rate | ≤2% | 0.7 |

| Impact Test | damage rate < 10% of samples | No damage |

| Hydro-static Pressure Test | 1 6 Mpa pressure for 1 hour under 20℃ temperature | No crack,no leakage |

| 4.2 Mpa pressure for 22 hours under 95℃ temperature | No crack,no leakage | |

| 3.8 Mpa pressure for 165 hours under 95℃ temperature | No crack,no leakage | |

| 3.5 Mpa pressure for 1000 hours under 95℃ temperature | No crack,no leakage |